Tips on angling head to the neck?

do you have any easy to do tips on how to attach the head at an angle? i am not that skilled with wood and don't have any fancy equipment beside a handsaw, drill and a file. So I am looking for the easiest way to do the tilt.

thanks

Tags:

Replies to This Discussion

-

Permalink Reply by Wichita Sam on February 17, 2009 at 6:46am

-

You could try building a mitre box at the angle you what the joint to be (most say 11 to 15 degrees) although I have done them up to 30* ... no problem. Just make the box deeper than your neck is wide...

Hope this helps...

the best,

Wichita Sam -

-

Permalink Reply by gene on February 17, 2009 at 10:55pm

-

haven't thought of a mitre box. i was more worried about making the joint between the neck and the head hold.

-

-

Permalink Reply by Wichita Sam on February 18, 2009 at 1:02am

-

First, get the cut right...(mitre box)... the simple wood glue (I use tightbond II) is enought. Some report using a little fine sand to provide enough friction so that clamping is easier... "cross clamping" where you clamp from the sides and then clamp across the cut works well for me... It isn't intuitive that something that simple works, but it does....

the best,

Sam

gene said:haven't thought of a mitre box. i was more worried about making the joint between the neck and the head hold. -

-

Permalink Reply by Jarmo Katajisto on August 11, 2014 at 7:37am

-

Here is my solution ...no glue, no cut and assembly ... only using grasp, knive, saw and so on ... and angle is enough.

http://www.cigarboxnation.com/photo/head-stock-290?context=user

-

-

Permalink Reply by Rob Bennett on August 11, 2014 at 8:21am

-

Angling the neck slightly back really helps a lot...Ive done it on my banjoleles using packing under the neck where it sits on the body to get a better set up...banjoleles have a through rod to the base so you can slacken off and tighten...on my cigar box I made a small wedge on the though neck by the base...the neck is glued to the top of the box...tho my box is upside down so the back opens freely as thats the lid....with me???

Try out the bridge in place and with a long straight edge balanced on the bridge and going up to the nut..you will see the path the strings will take...make your decision from this...i think there are recommended distances strings should be from the fret board at the nut end and at the 12th

Its fiddly and you need a temporary build to find out what angle you will need

- Attachments:

-

-

P8060028.jpg, 80 KB

P8060028.jpg, 80 KB

-

-

-

Permalink Reply by Tom Drommond on August 11, 2014 at 9:17am

-

an angled peghead is not necessary to get proper string tension across the nut. 90% of what I build does not have an angled peghead. The trick I learned is to leave the strings long and wind them onto the tuning peg until it almost touched the face of the peghead.

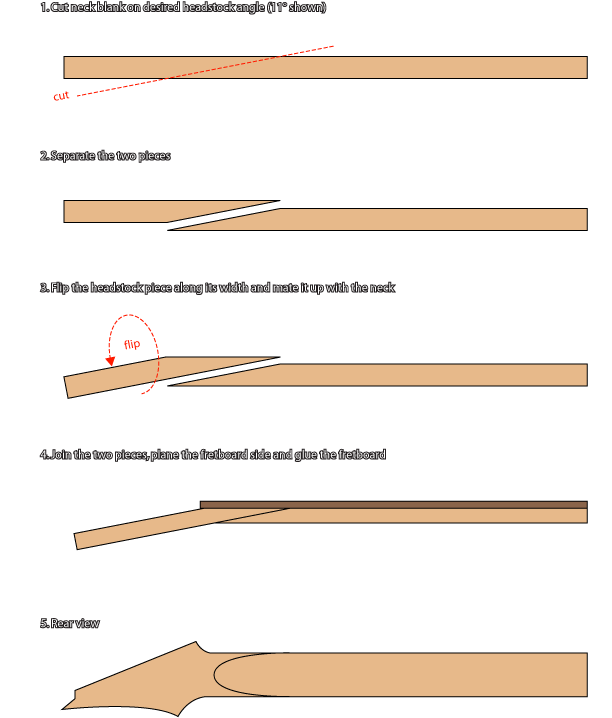

If you want an angled peghead, the easy way is a scarf joint

-

-

Permalink Reply by Rob Bennett on August 11, 2014 at 9:42am

-

Sorry my reply earlier was for Gary Decker but I cant find his thread

-

-

Permalink Reply by Murray on August 11, 2014 at 10:58am

-

Last ones I made I had trouble setting the neighbor's table saw to the angle I wanted with a fence on the side I wanted it...while fighting with the saw I cut them at 30 degrees and wondered what would happen.

I had read that 15-17 was typical with guitars...I see someone here mentioned 11-15.

To put it into perspective, lutes (those old European bowl-back instruments) are nearly 90 degrees. I read some history on them and the luthiers used a somewhat higher angle with low-tension gut strings to guarantee a good positive contact with the nut...over time, it became extreme but is almost entirely style/tradition.

Many Fender guitar necks don't have an angle, at least not an angled miter 'scarf joint' (no idea why they call it that, but scarf and neck seem to go well together)...instead, the flat portion where the tuners go is thinner so there ends up being an angle from the nut to the tuners.

I think that is the critical part (and don't know if it is as critical with fretless instruments played with slides).

If you have clearance so the strings get where they are supposed to from the neck to the tuners, the nut 'break angle' which is the angle at which the string leaves the nut can be shaped later.

If you're using threaded rod and whatever else CBG'ers stuff under the strings for a nut, I guess a lot doesn't play by 'the rules'. If you have to monkey with something there it get it to work without buzzing and other rude noises, it's usually the angle the string takes at the nut & the saddle.My 30 degree headstocks are kind of stagnating...I made some airplane tuner knobs and didn't anticipate how much turning radius they needed and had already cut the first headstock too short!!

I think I'll glue some kind of decorative contrasting wood on the short headstock to make it longer, and maybe a thin piece over the glued-together pieces so I don't worry about when I feel like it coming apart.I will try a mitre box too...My hand cuts look pretty bad so I was hoping power tools would help the appearance.

-

-

Permalink Reply by Tom Drommond on August 11, 2014 at 1:48pm

-

-

Permalink Reply by Ken Henry on August 12, 2014 at 6:05am

-

I measure out 3 inches on the side of my 1X2 maple neckstock and mark off from corner to corner and then cut it with my bandsaw or tablesaw and then flip it as

Tom Drommond described and that gives me the perfect angle. You can get a plastic mitre box really cheap and make your own cutting slots according to your marks on your board. Hope this helps

-

-

Permalink Reply by gary sheldon on August 11, 2014 at 7:08pm

-

Here is how I have done it. The system is from a YouTube video on building CBGs. This works, is strong and not too hard to do with hand tools.

Measure down about 4.75 inches from the end of the neck. Make a mark. Draw a line across the fretboard side of the neck. Make tic marks with a pencil on the 2 sides of the neck at the line you just drew. Draw a straight line from the tic mark to the end of the neck at the back side of the neck. That line will be the face of the headstock. With a handsaw, carefully cut through the neck following that line. When you are finished, the scrap that you have removed will be roughly a pie shaped wedge going from 0 to 3/4" over about 4.75". You then glue the scrap wedge to the back of the neck, being sure to glue factory face to factory face, thicker part at the end. Clamp and let the glue dry. Next, you will sand or file those 2 surfaces flat. Cutting with a hand saw is not going to be too accurate, but it will work out ok because you will remove around 1/8" from each of the two surfaces. The final thickness

needs to be the proper thickness for the tuners to stick through with enough room on the spindle for a few wraps of the guitar string.

After that, you will want to add a 1/4" "ear" on each side with glue to make the headstock wider.

The weak point of a guitar is the headstock joint. With this method you will have a super strong joint that will never fail. That is due to the large surface area that you are glueing.

The last step is to trim the end of the headstock with your saw. I do this after the tuners are installed and I know exactly how long I want it to be.

-

-

Permalink Reply by Tom Drommond on August 12, 2014 at 5:24am

-

I don't think you've added enough angle to make a difference besides cosmetic. The peghead break angle is used to increase the force holding the string in the nut slot. Increasing the distance from the top of the nut to the top of the peghead serves the same purpose. When I make my necks I use a piece 1/2 inch thick stock on bottom, a 1/4 inch filler and 1/4 inch fingerboard. That gives 1/2 inch drop from the nut to the peghead and is probably more break angle than you have with the scarf joint and shallow distance from the nut to the face of the peghead.

-

Recommended Links & Resources

- CigarBoxGuitar.com - the knowledgebase of the homemade music movement.

- Cigar Box Music - How-to-Build CBGs DVDs, How to Play CBG and more!

- 3-String-Guitar.com - John "Red Dog" McNair's unique take on cigar box guitars and their history - lots of historic photos!

- The Cigar Box Guitar Manifesto - the mission statement and rallying cry for the Cigar Box Guitar Revolution.

Discussion Forum

Cutting deep boxes in half

Started by Justin Stanchfield. Last reply by Taffy Evans Mar 20. 9 Replies 2 Likes

Attention 1st time builders!

Started by BrianQ.. Last reply by MadGomer Feb 27. 2 Replies 4 Likes

Brickhouse CBG Wiring

Started by Ian Boyd. Last reply by Ian Boyd Dec 11, 2023. 1 Reply 0 Likes

Fretless fret markers

Started by Michael Myers. Last reply by Michael Myers Apr 20, 2023. 8 Replies 0 Likes

canjo building and tuning

Started by Brenda. Last reply by MadGomer Dec 3, 2022. 5 Replies 0 Likes

Minimum tools needed

Started by Wichita Sam. Last reply by Taffy Evans Nov 14, 2022. 21 Replies 1 Like

High G problem

Started by Michael Myers. Last reply by Taffy Evans Nov 3, 2022. 4 Replies 0 Likes

Doubling the high string

Started by Robert Killen. Last reply by Paul Craig Oct 14, 2022. 23 Replies 2 Likes

Aluminum License Plate

Started by Larry Sobol. Last reply by Larry Sobol Oct 1, 2022. 6 Replies 2 Likes

C. B. Gifty three string fretless kits.

Started by jon neet. Last reply by Taffy Evans Aug 16, 2022. 6 Replies 1 Like

Frettin' and stainin'

Started by Doug Laffin. Last reply by Order99 Aug 11, 2022. 4 Replies 1 Like

Bolt on neck to a set neck body?

Started by Paul Craig. Last reply by Paul Craig Jul 17, 2022. 14 Replies 1 Like

Locations

Started by Roy Smith. Last reply by the anonymous pick May 15, 2022. 2 Replies 0 Likes

Help please re Bento Box Uke "nut"

Started by Al Lobe. Last reply by BrianQ. May 10, 2022. 18 Replies 0 Likes

Clarification on pick ups

Started by Michael Myers. Last reply by Taffy Evans May 6, 2022. 5 Replies 1 Like

Licence plate cbg

Started by Michael Myers. Last reply by Michael Myers May 2, 2022. 5 Replies 0 Likes

Builder's Tips

Started by Wichita Sam. Last reply by MadGomer Feb 23, 2022. 2 Replies 4 Likes

Getting there but needing advice/help please.

Started by Lionhound. Last reply by MadGomer Feb 18, 2022. 8 Replies 0 Likes

Tres Cubano Build

Started by Paul Craig. Last reply by Paul Craig Dec 9, 2021. 18 Replies 2 Likes

CB Gitty Country Roads Banjo kit

Started by Ken Hope. Last reply by Christopher G Daniels Nov 29, 2021. 4 Replies 1 Like

Blog Posts

I'll be fashionable this summer =)

Posted by Vlad on March 31, 2024 at 11:48pm 0 Comments 1 Like

Everyone can make CBG. And I did it =)

Posted by Vlad on March 6, 2024 at 2:32am 5 Comments 2 Likes

.✨. Cover Me ..♪♫•*¨*•. ~ the Delta Blues Outlaws

Posted by billy jones bluez on February 28, 2024 at 2:09pm 0 Comments 0 Likes

Q&A with Arkansas-based talented blues musician Billy Jones, one of the very best authentic modern artists

Posted by billy jones bluez on February 17, 2024 at 11:00pm 0 Comments 0 Likes

Big Power Bank for Small CBG =)

Posted by Vlad on February 11, 2024 at 1:06am 1 Comment 1 Like

Latest Activity

Cigar Box Guitar 106 now for sale 🙌

CigarBoxGuitar.com Knowledgebase Articles

Events

-

Republic of Texas CBG Festival (8th Annual)

May 11, 2024 from 11am to 8pm – Speakeasy Grill

0 Comments 0 Likes

-

20th Annual Cigar Box Guitar Festival (Day 1)

May 30, 2024 from 6:30pm to 10pm – The Casual Pint of Huntsville

0 Comments 0 Likes

Music

© 2024 Created by Ben "C. B. Gitty" Baker.

Powered by

![]()

Cigar Box Nation is presented by C. B. Gitty Crafter Supply, your one-stop-shop for Cigar Box Guitar parts and accessories!